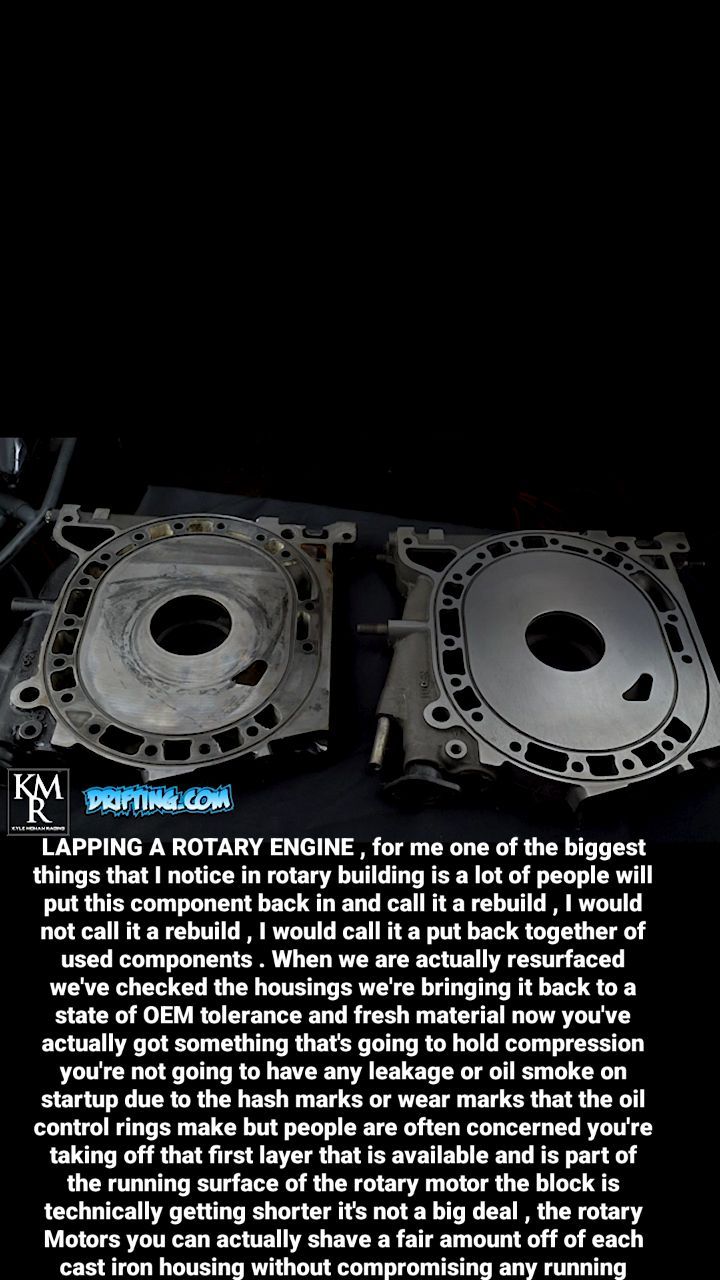

for me one of the biggest things that I notice in rotary building is a lot of people will put this component back in and call it a rebuild , I would not call it a rebuild , I would call it a put back together of used components . When we are actually resurfaced we've checked the housings we're bringing it back to a state of OEM tolerance and fresh material now you've actually got something that's going to hold compression you're not going to have any leakage or oil smoke on startup due to the hash marks or wear marks that the oil control rings make but people are often concerned you're taking off that first layer that is available and is part of the running surface of the rotary motor the block is technically getting shorter it's not a big deal , the rotary Motors you can actually shave a fair amount off of each cast iron housing without compromising any running aspects

Watch 2024 Formula Drift ROUND 5 Live

July 20, 2024Addicted to Boost Sticker

June 26, 2024

Comments are closed.

Test

-

Watch 2024 Formula Drift ROUND 5 Live

July 20, 2024 -

Addicted to Boost Sticker

June 26, 2024

Test

-

Watch 2024 Formula Drift ROUND 5 Live

July 20, 2024 -

Addicted to Boost Sticker

June 26, 2024

Test

-

Watch 2024 Formula Drift ROUND 5 Live

July 20, 2024 -

Addicted to Boost Sticker

June 26, 2024

ADD TEXT